Screw cap bag juice production line

The capping bagged juice production line consists of various mechanical equipment, including water treatment, CIP cleaning system, self-bag filling and sealing machine, etc. It is simple to install and operate, allowing you to quickly produce finished products. Then sell.

place of origin :

AnhuiHarbor :

ShanghaiMinimum order quantity :

1 setDate of delivery :

60 daysScrew cap bag juice production line

Product introduction:

The screw cap bagged juice production line is used to produce screw cap bagged juice. This production line treats well water or river water into pure drinking water through water treatment facilities. Various food additives are then added to the purified water and juice drinks are made through a heating shearing device. The prepared juice is sterilized by UHT high temperature treatment. The filling machine fills the juice into screw-cap bags, and finally produces juice in screw-cap bags for easy sales. The output of the production line can be customized and adjusted according to the buyer's requirements. If the filling machine is replaced, the production line can also be transformed to produce bottled and bagged juice.

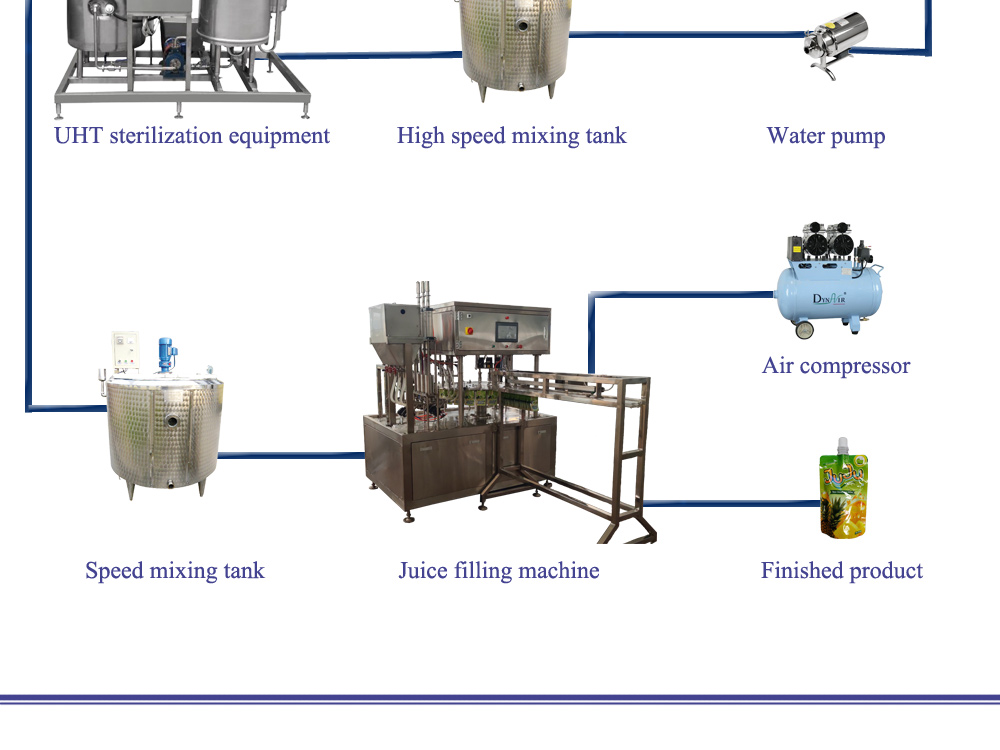

Production line layout:

After-sales service:

If you need to install the product, we can send engineers there. The customer is required to pay the engineer a salary of $150 per day, accommodation and meals during the installation period, as well as round-trip airfare for the engineer.

The whole machine is guaranteed for one year, and the core components are guaranteed for two years.

Long-term supply of machine parts and packaging materials.

For inquiries about our products or pricelist, please leave to us and we will be in touch within 24 hours.

Email : kocomachinery@gmail.com

Address : ZHESHANG START BUSINESS MANSION ROOM NO.1407 NO.103 KEXUEDADAO ROAD, HEFEI ANHUI, CHINA.