Screw cap bag juice beverage production process

Jun 06, 2024

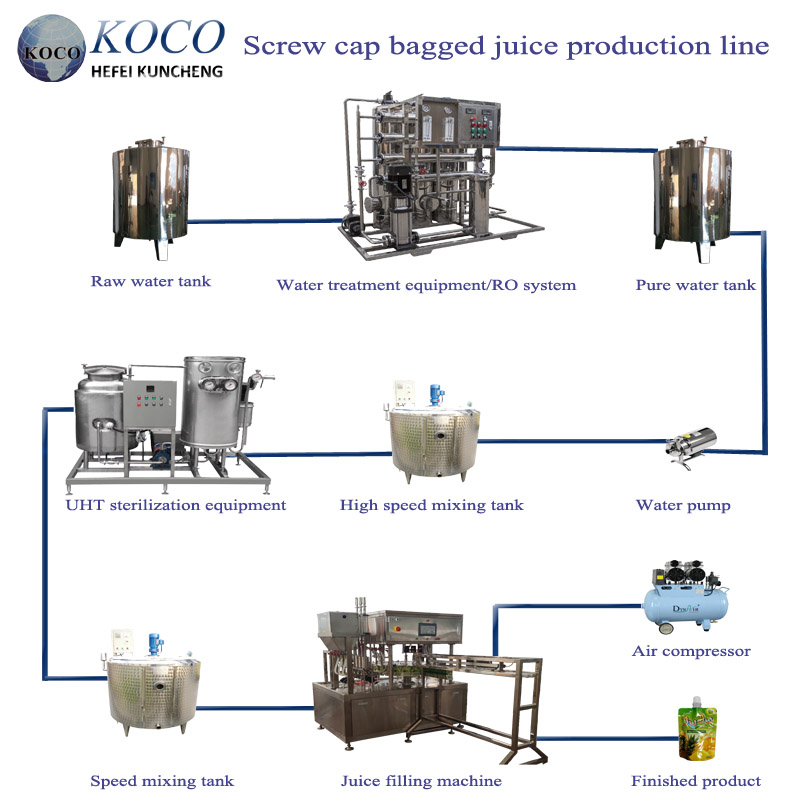

The screw-on capping juice beverage production line refers to a packaging form that uses a rotary cap to seal, usually used to load juice and other beverages. Step 1 First, you need to prepare the raw material formula of the juice or flavored beverage.

Step 2 According to the product formula, mix the prepared raw materials in a certain proportion to ensure the consistency of taste and quality.

Step 3 After the mixed juice is evenly stirred, it is sterilized to ensure the safety and long-term preservation of the product.

Step 4 Fill the prepared juice into the screw-on capping bag through the screw-on capping filling machine, and then tighten the cap through the screw-on capping device on the screw-on capping machine to maintain the sealing.

Step 5 Perform quality inspection on the packaged juice beverage to ensure that the quality of the product meets the standard requirements.

Because the bag is printed in advance, it can be packed into boxes after filling. In addition, the machine has a printing date function, and the date of inspection is completed after packaging.

The above is the general production process of screw-on capping juice beverages. In actual production, it will be adjusted and optimized according to specific equipment and process requirements.