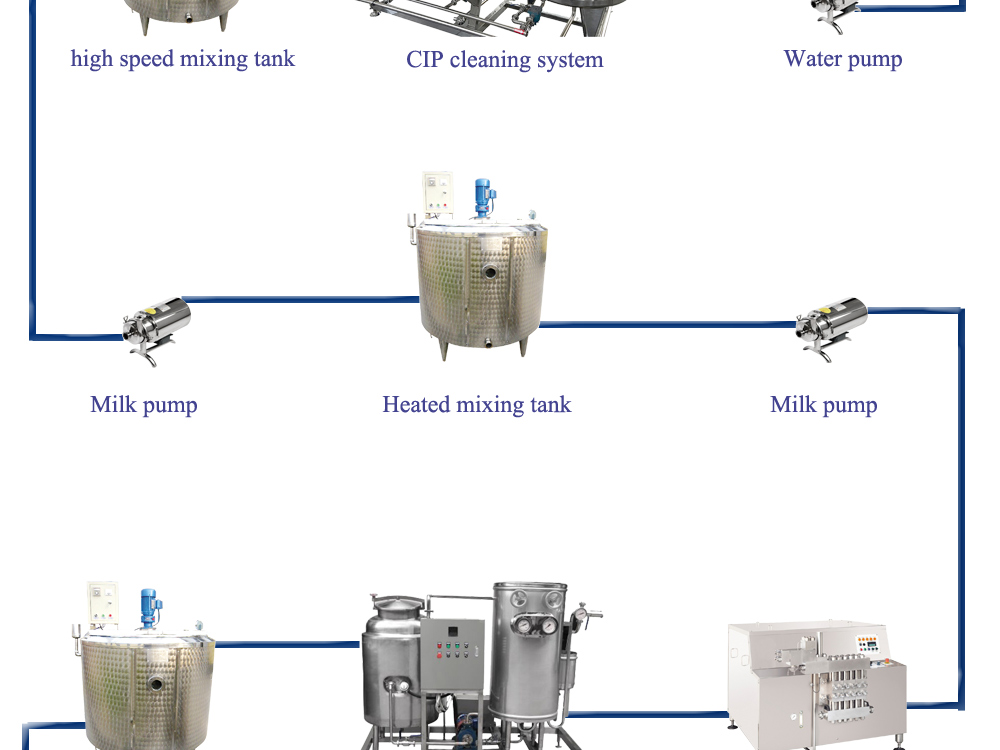

Cup yogurt production lines usually include the following series of processes and equipment:

1. Preprocessing part:

a) Receiving and storing raw materials: raw materials include milk, milk powder, food additives, etc.

b) Cleaning and Disinfection: Clean and disinfect equipment and containers to ensure sanitary conditions.

c) Mixing and adjustment: Mix and adjust different ingredients according to the recipe requirements.

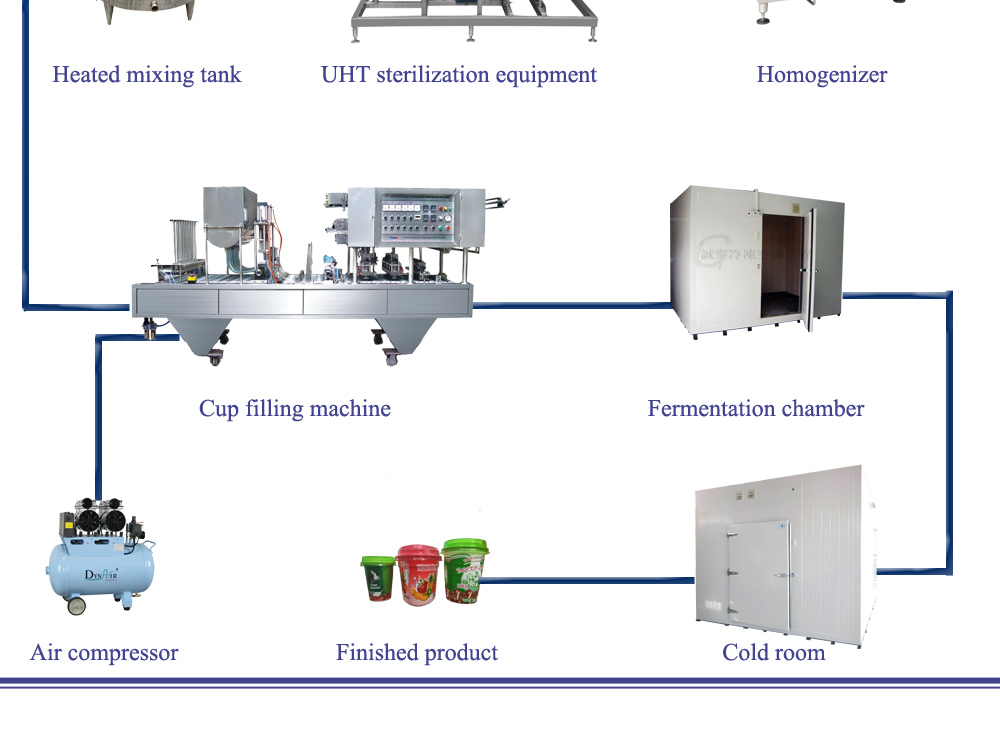

2. Heating and sterilization:

a) Sterilization: Sterilize the mixed liquid to destroy possible harmful bacteria and bacteria.

b) Heating: Heating the liquid to achieve certain temperature requirements.

3. Filling and sealing:

a) Put the sterilized liquid yogurt from the large container into a small cup to ensure the sealing and shelf life of the product. You can use an automatic cup filling machine to operate.

4. Packaging and Labeling:

a) Pack the sealed cup yogurt, and you can choose to put a certain number of cup yogurt into the box.

b) Label the packaging box with product information, nutritional ingredients and barcodes.

5. Fermentation and refrigeration:

a) Place the filled yogurt into the fermentation chamber for fermentation. This step usually requires temperature and time control to ensure the quality of the yogurt.

b) After fermentation is completed, the yogurt will be placed in the refrigerator and quickly cooled to stop the fermentation process and maintain its taste and nutritional value.

6. Testing and quality control:

a) Conduct quality inspection on cup yogurt, including product appearance, weight, sealing, nutritional content, etc.

b) Make necessary adjustments and processing to ensure compliance with quality standards.

7. Finished product storage and distribution:

a) Storage and distribution of finished products to ensure that products are stored at appropriate temperatures and delivered to the point of sale.

Please note that specific cup yogurt production lines may vary depending on the manufacturer's size and process flow. The above description only provides a general production line process flow, and the details need to be adjusted according to the actual situation.

Whether you choose a standalone yogurt filling machine or a complete production line, our team of in-house R&D experts will help you select the equipment you need and work with you on project planning to develop the best solution for your business.

For inquiries about our products or pricelist, please leave to us and we will be in touch within 24 hours.

Email : kocomachinery@gmail.com

Address : ZHESHANG START BUSINESS MANSION ROOM NO.1407 NO.103 KEXUEDADAO ROAD, HEFEI ANHUI, CHINA.